AUTOMATIC, SEMI-AUTOMATIC AND MANUAL WORK STATIONS

Mtc produces:

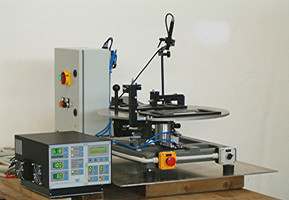

- automatic and semi-automatic welding systems;

- automatic and semi-automatic high production welding stations, designed and built in accordance with client specifications;

- rotary - tilting - linear tables;

- bench part holders for the manual working of parts, specifically designed in consideration of the parts to be produced.

AUTOMATIC AND SEMI-AUTOMATIC AUTOMATIONS

MANUAL TOOLS

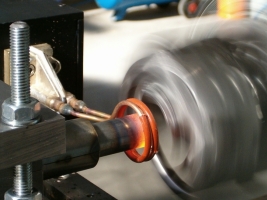

TUBE CLOSURE System for the closure of tubes with induction

- working of tubes with diameter from 10 to 60 mm.;

- thickness from 0.5 to 3 mm.;

- without weld material;

- guaranteed airtight seal;

- fast execution, high productivity;

- work station complete with mechanical parts and even double stations for simultaneous closure of both ends.

General features:

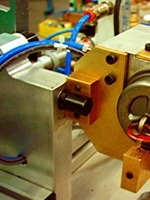

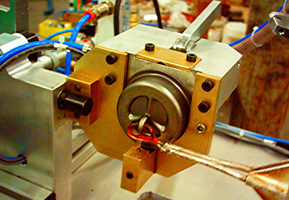

- system for deformation of ends of circular tubes;

- processing of iron, steel and stainless steel tubes;

- each unit works one end of the tube;

- possibility for double stations for simultaneous execution on both ends of tube;

- possibility to work welded tubes thanks to a tube locking system.

Procedure:

- possibility to obtain complete and sealed closure;

- possibility to obtain partial closures (with non-gauged holes);

- possibility for deformation of tubes for following profiles: round, tapered, ribbed, ogival and flat.

- possibility for automated loading/unloading;

- working of diameters from 10 to 60 mm. (depending on profile);

- working of thicknesses from 0.5 to 3 mm (depending on profile and diameter of tube);

- minimum tube length:

- 200 mm. for single station, 400 mm. for double station (depending on diameter, thickness and profile)

Technical features: Generator power used: MTC MF generators from 6/8 kW or HIGH POWER 10/12/15 Kw depending on diameter and thickness of tube,